Our Models

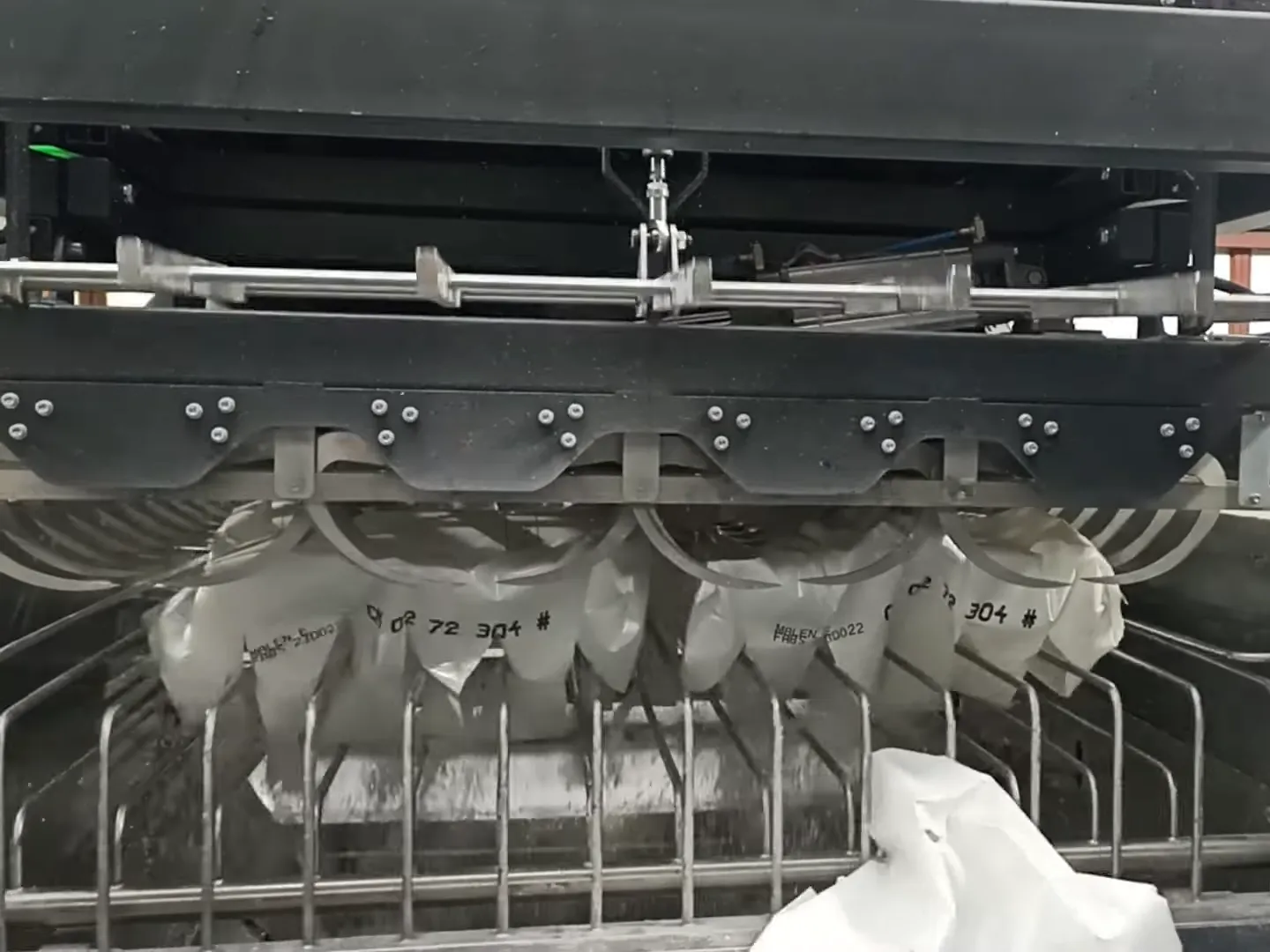

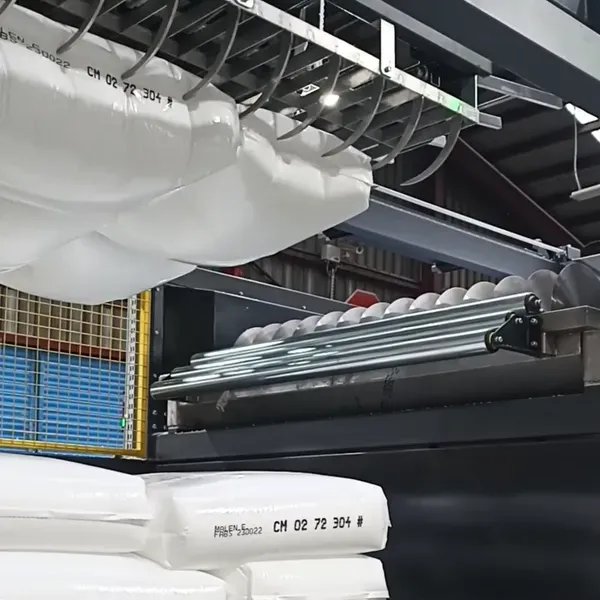

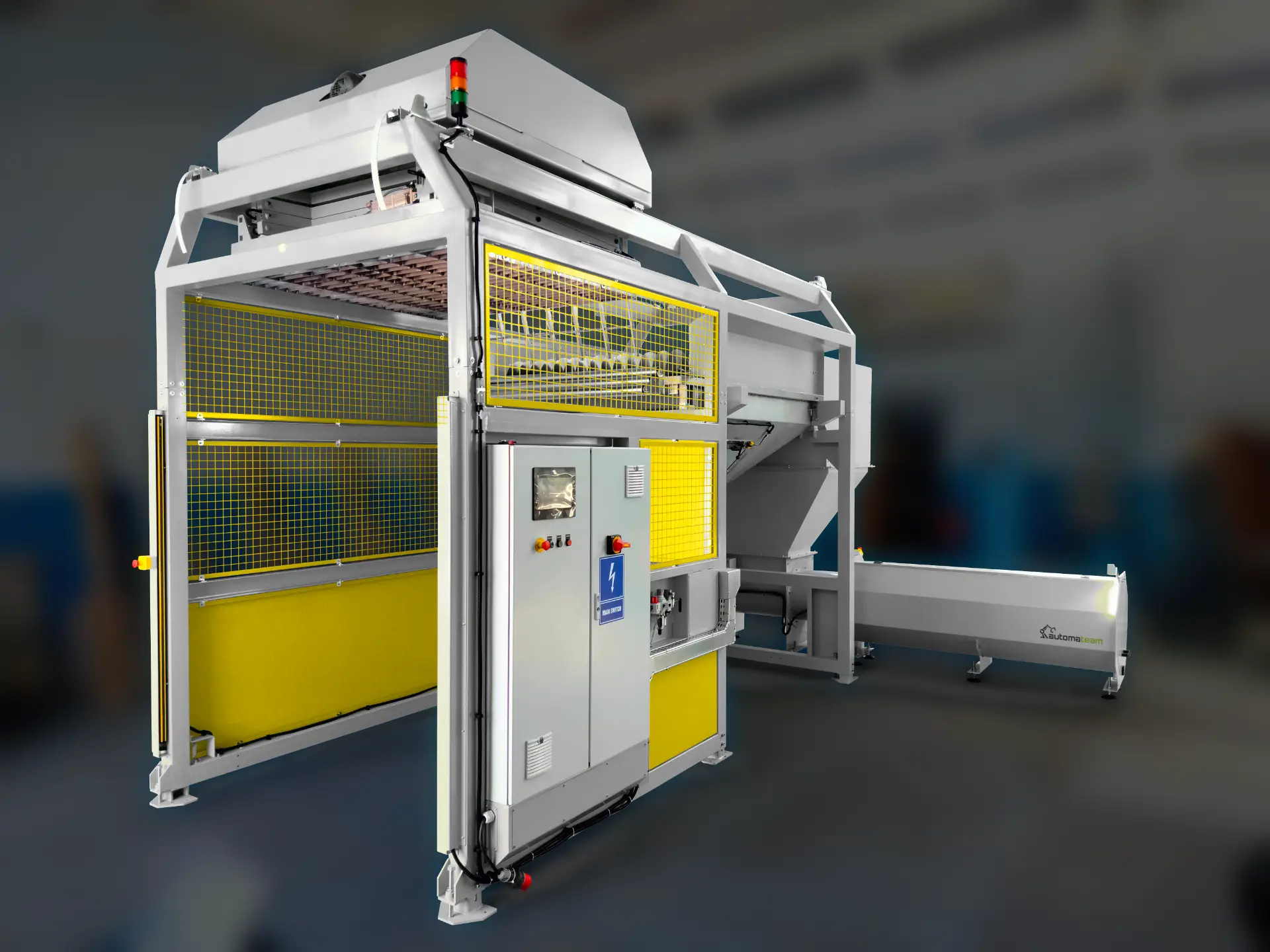

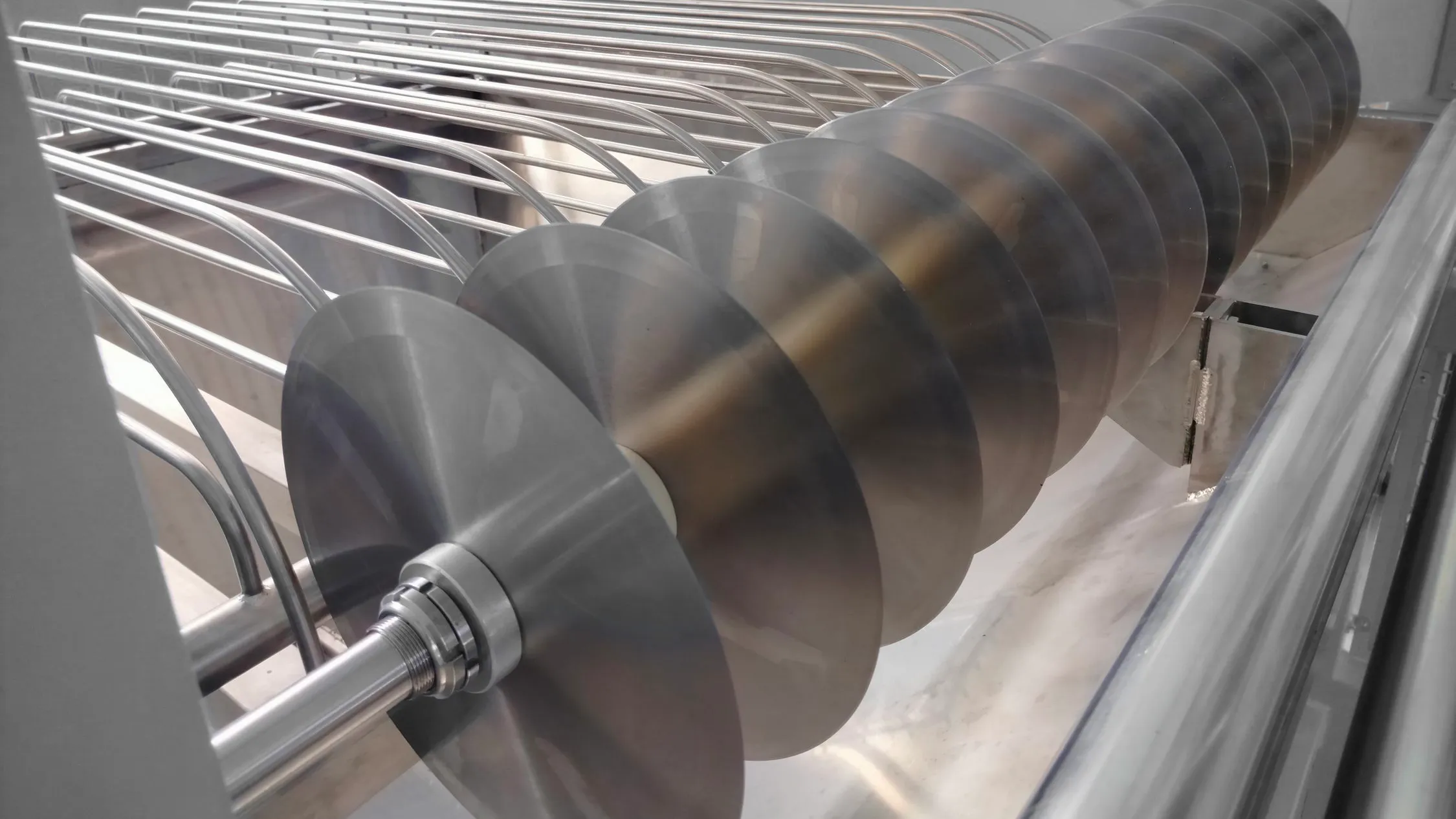

A universal, high-performance model ideal for most industrial applications.

High Efficiency

Empties up to 880 bags per hour, depending on model and configuration.

Extensive Integration Capabilities

Can be integrated with dosing valves, blowers, horizontal hydraulic presses, and more.

Full Customization

We offer the option to modify both the cutter and any peripheral devices.

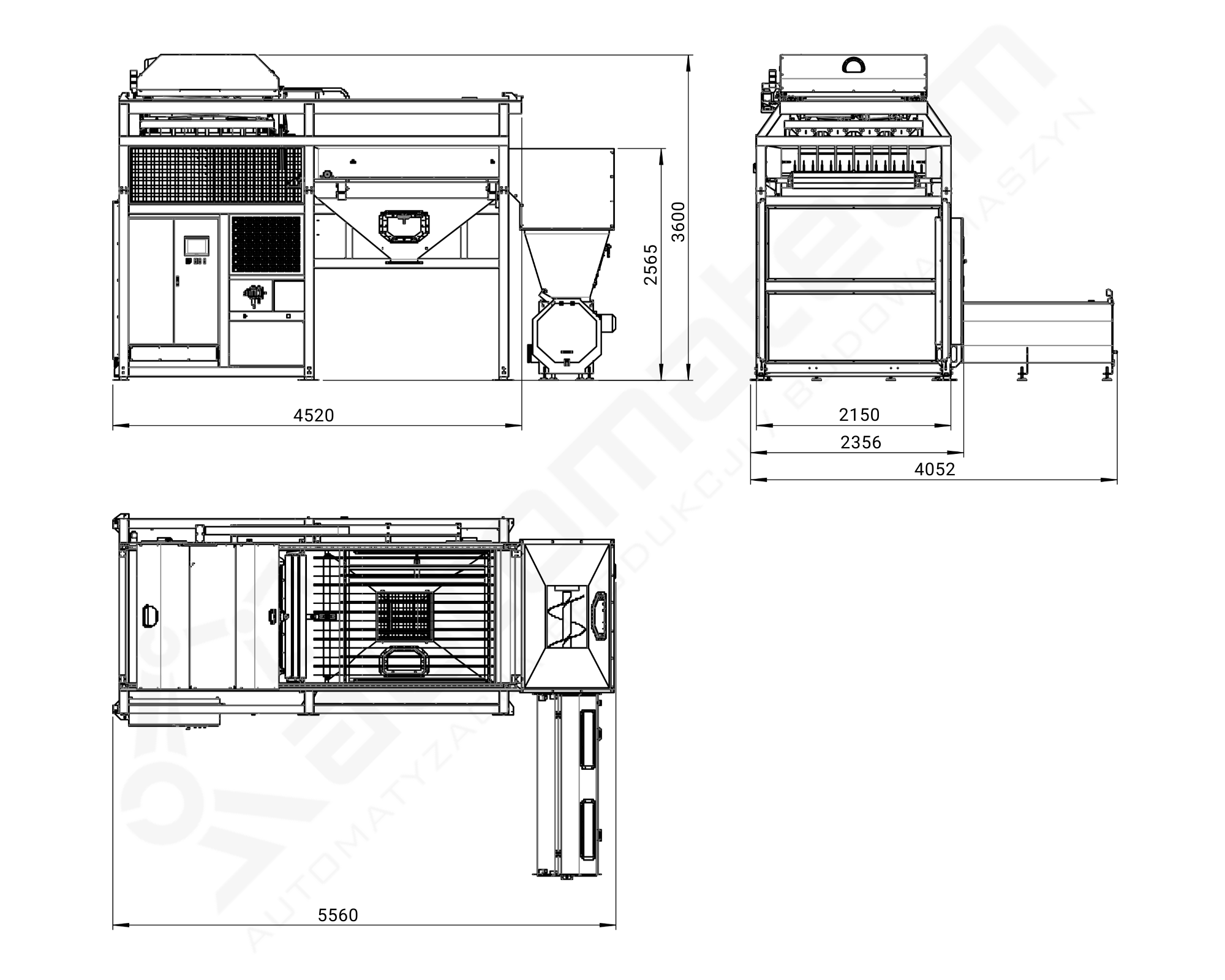

Basic Technical Specifications

| Capacity | 12-22 tons/h |

| Installed Power | 10 kW |

| Power Supply | 3x400V/50Hz |

| Air Pressure | min. 6 bar |

| Air Consumption | 400 Nl/min |

| Cutter Dimmensions (LxWxH) | 4520 x 2356 x 3600 mm |

| Operating Temperature | 5-40°C |

| Noise Level | < 75 dB(A) |

Default configuration includes the UDR Cutter with an empty bags compactor

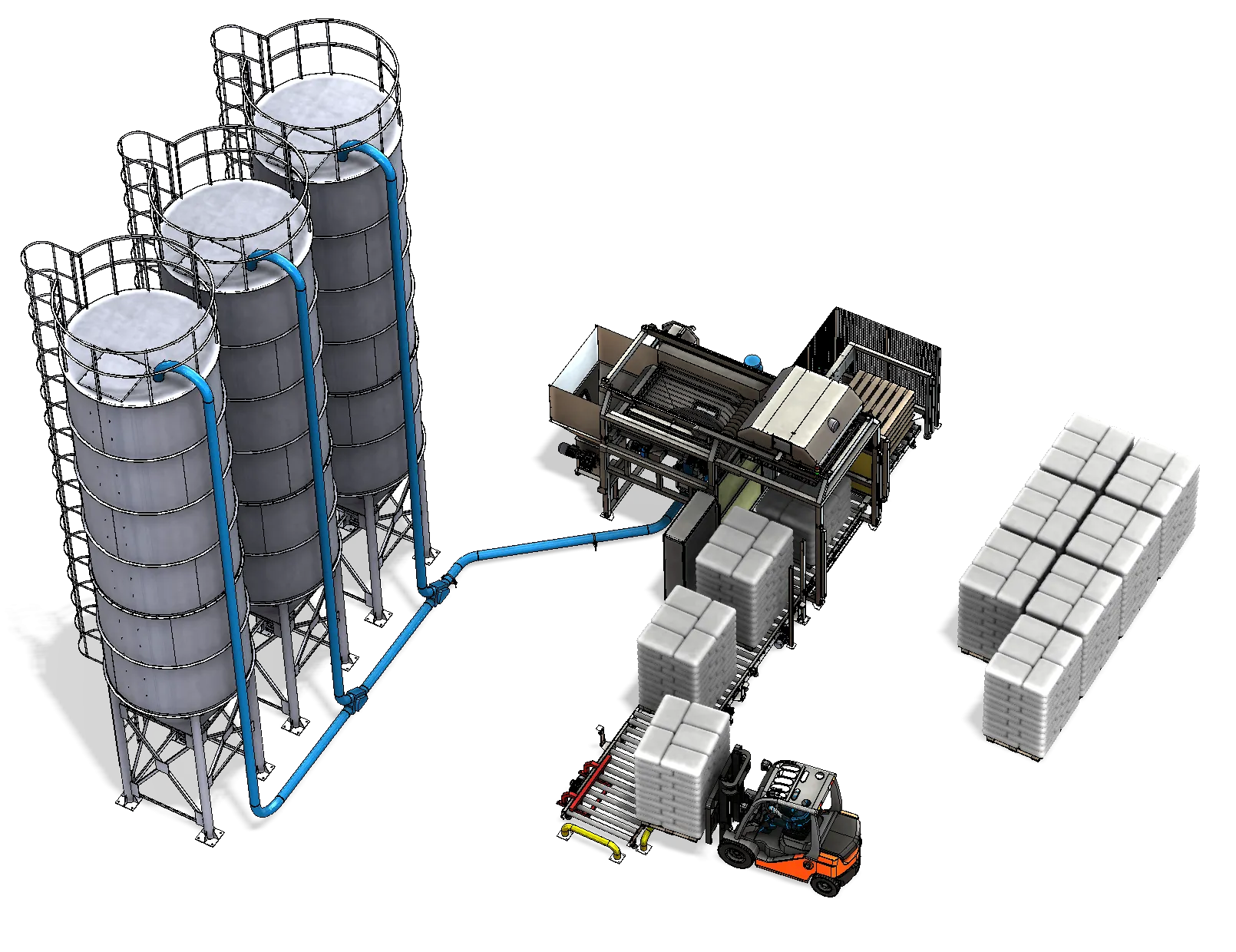

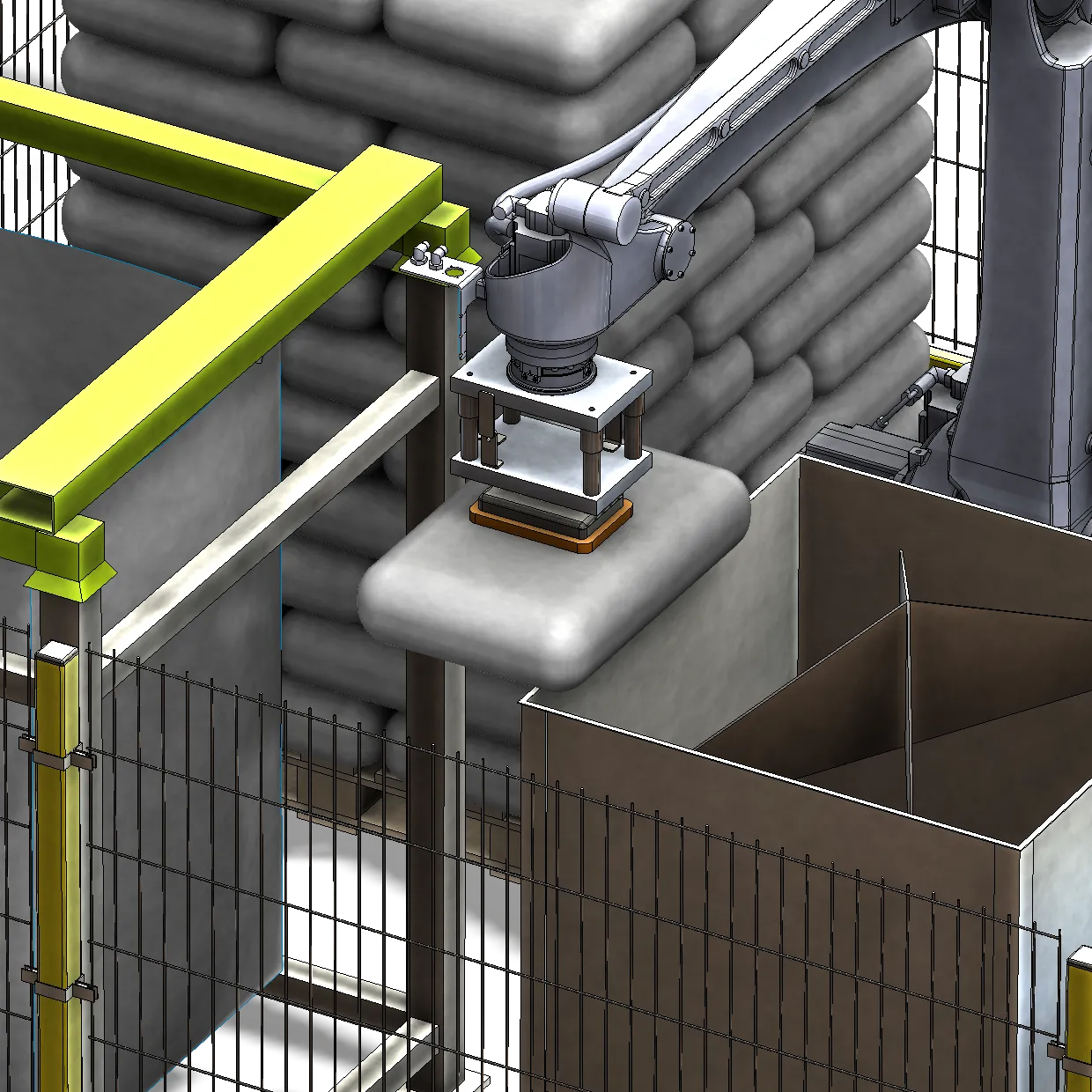

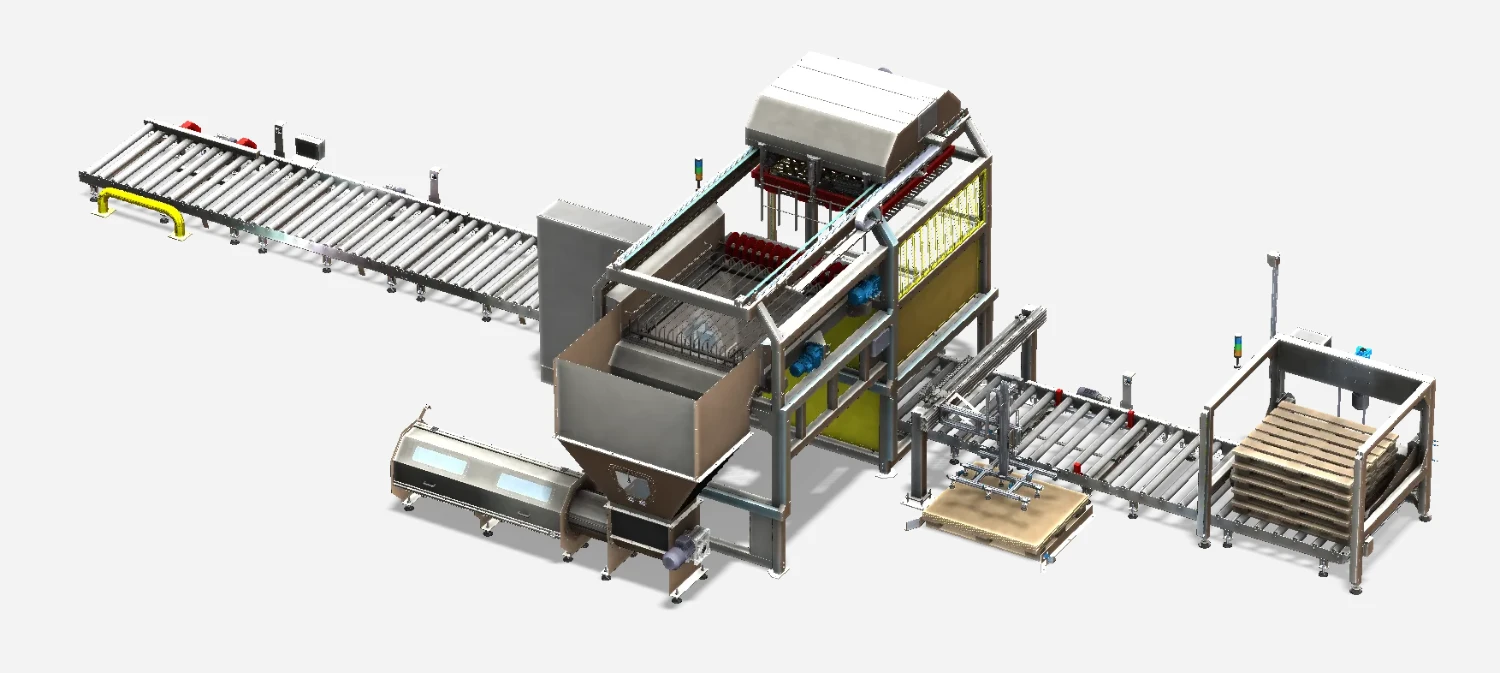

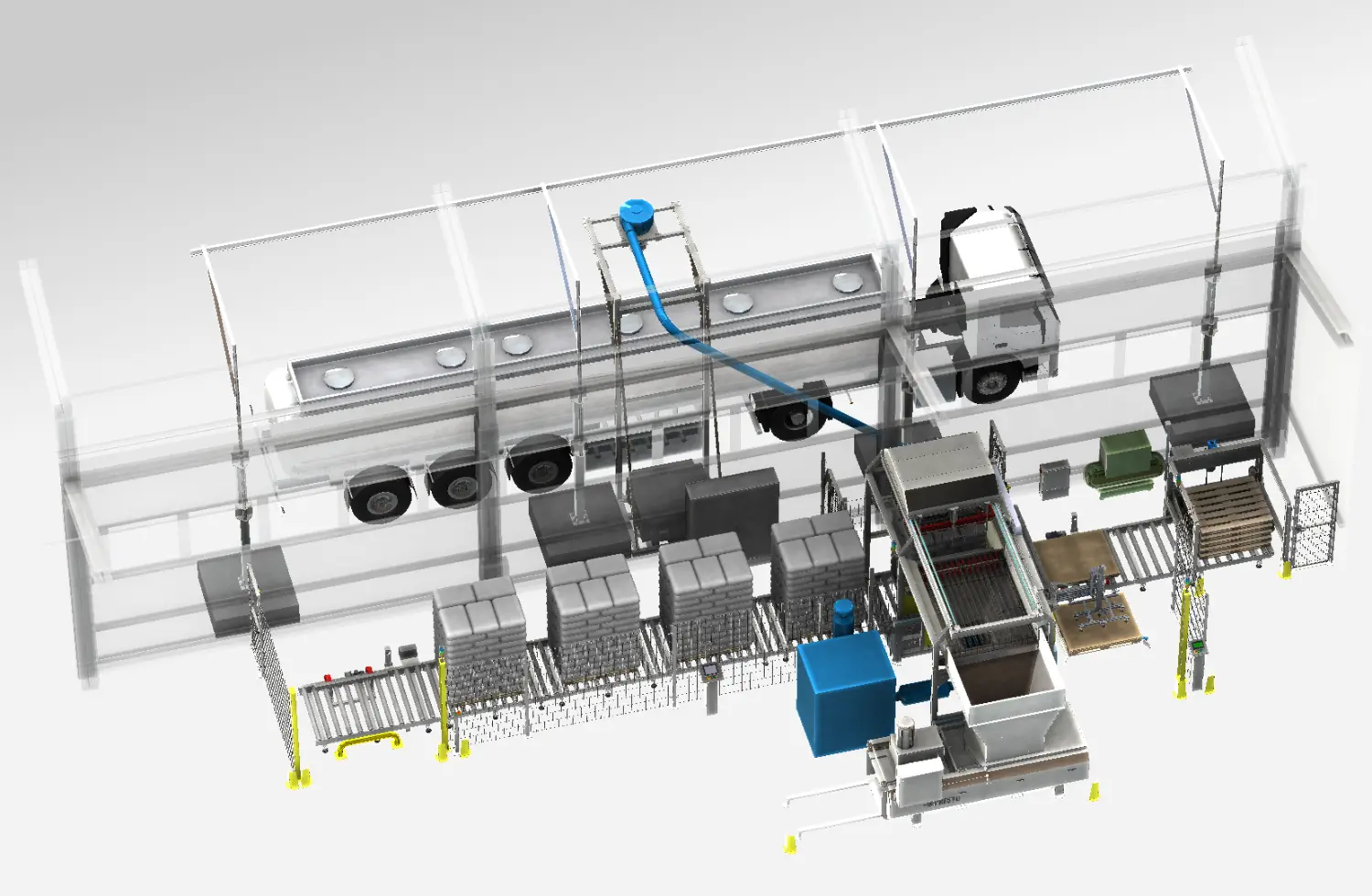

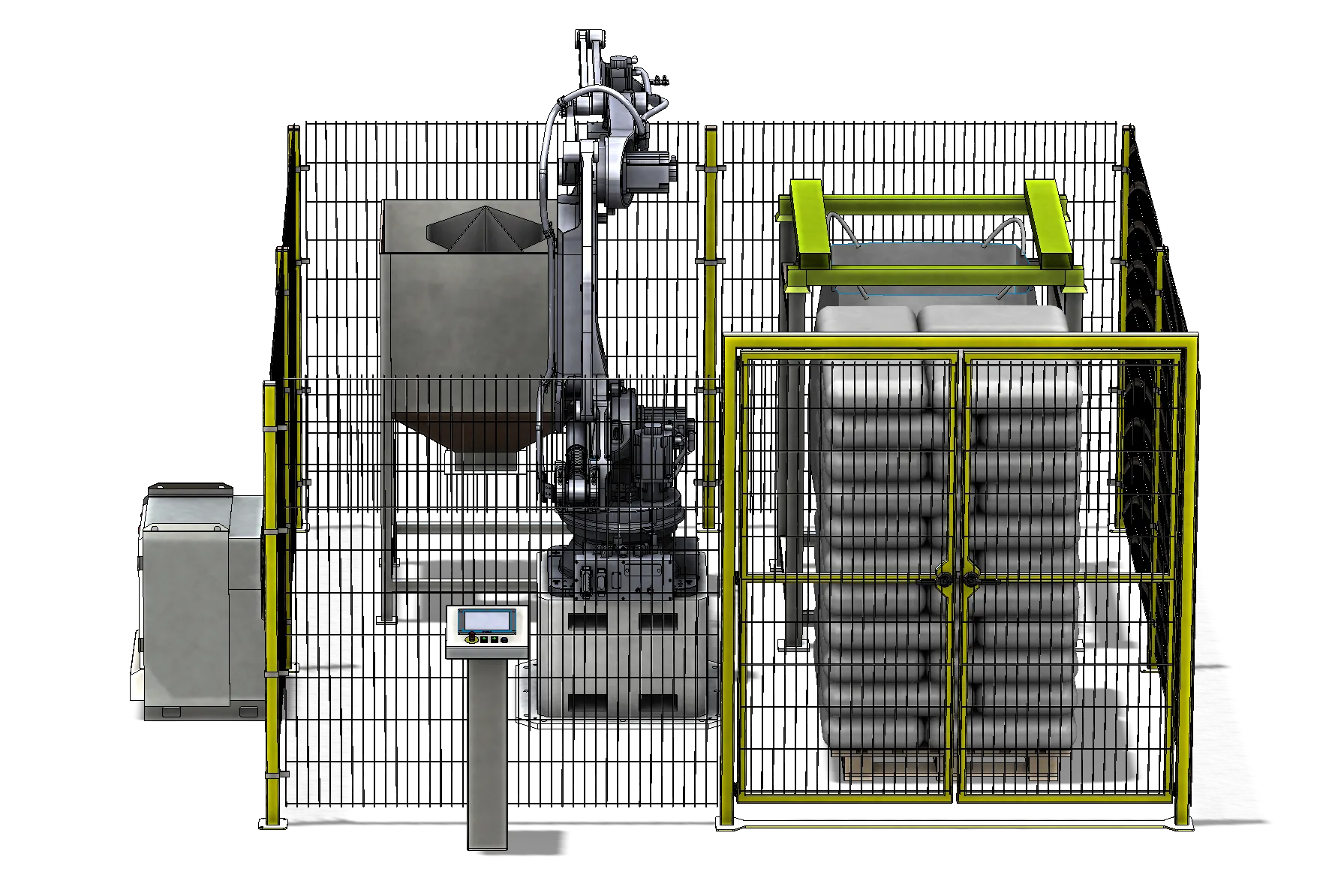

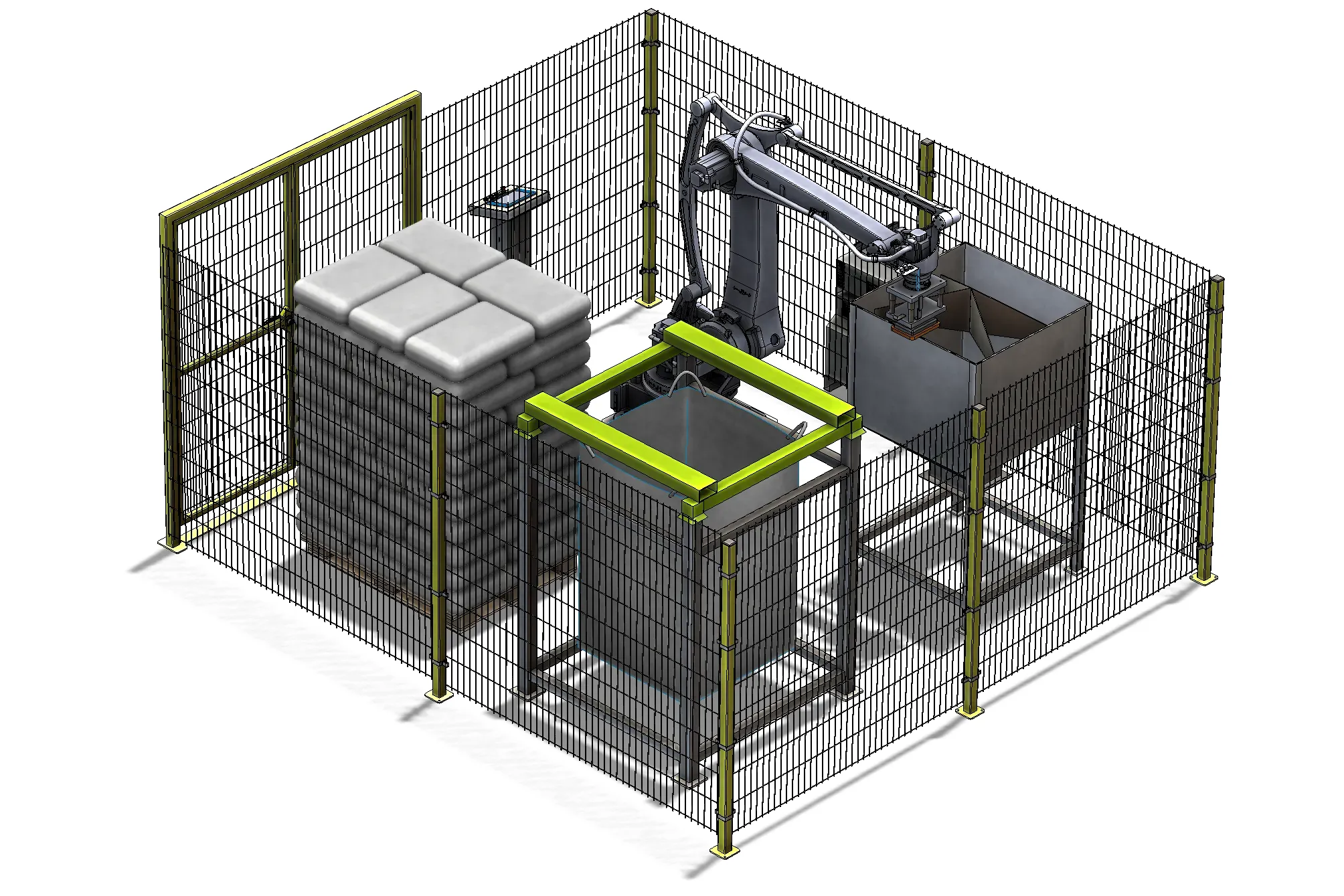

An advanced high-capacity bag emptying line with full process automation and monitoring.

Process automation using an industrial robot with a vision system and specialized gripper. Flexible handling of different types of granulate.

Supports Multiple Types of Granulate

Capable of depalletizing from multiple pallets simultaneously, transferring to separate tanks.

Versatility and Cost-Effectiveness

Highly flexible solutions with numerous modifications and applications.

Vision System

Effectively detects the position of individual bags on a pallet prior to gripping.

Full Customization

We can tailor the robotic cell to meet specific project requirements.

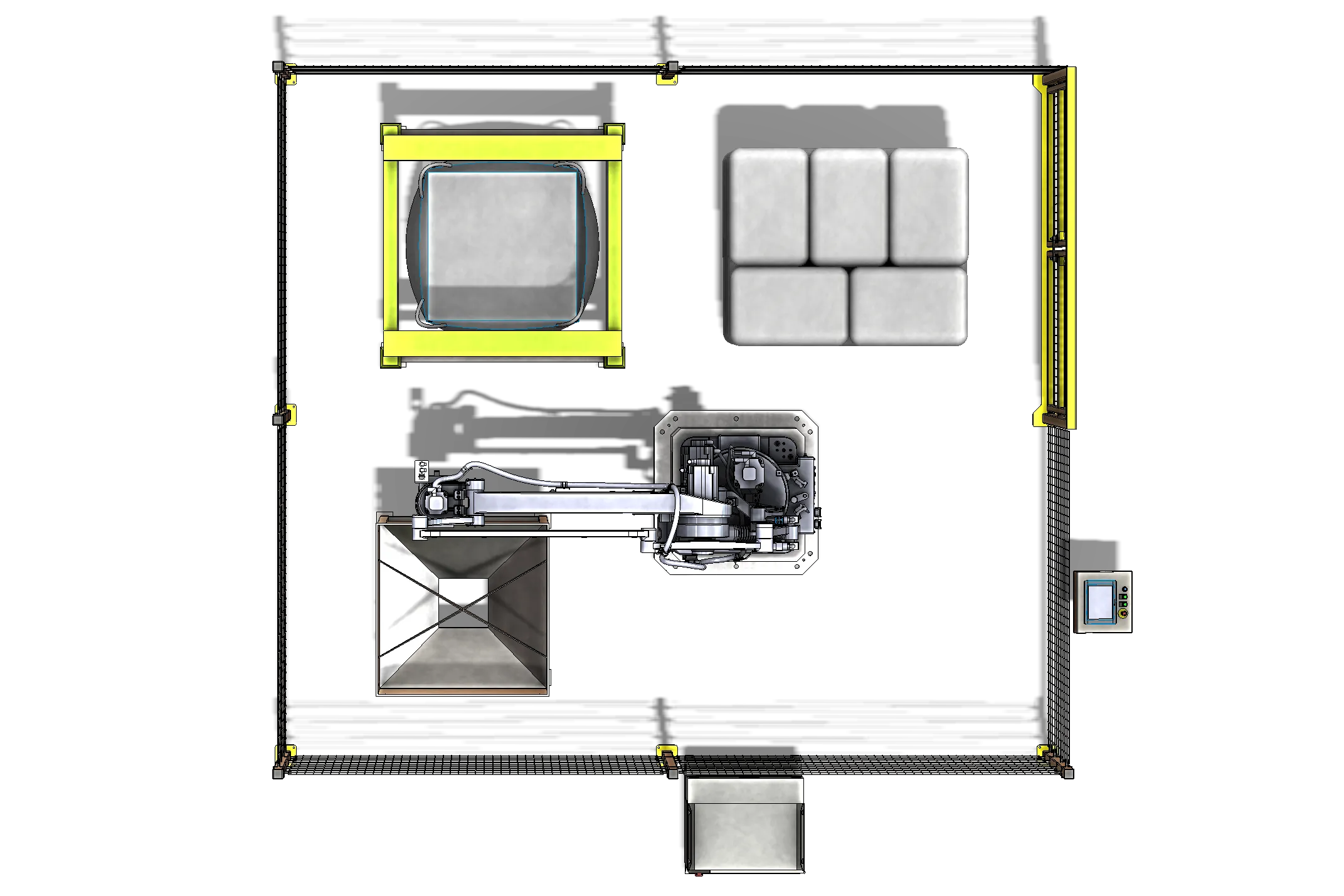

Basic Technical Specifications of the Robotic Station

| Capacity | 5-8 tons/h |

| Installed Power | ~5 kW |

| Power Supply | 3x400V/50Hz |

| Air Pressure | min. 6 bar |

| Station Dimensions (L×W×H) | ~ 5000 x 5200 x 2900 mm |

| Operating Temperature | 5-40°C |

| Noise Level | < 75 dB(A) |

Our Benefits

High Efficiency

Safety

Customization

Automation

Remote Service

Quality and Durability

FAQ

What You Need

to Know